EnviroBuild is proud to be the first company in the UK to publish the environmental impact of its composite products through an Environmental Product Declaration (EPD). This significant milestone marks the beginning of a new era of transparency and sustainability in the building materials industry.

An EPD provides an in-depth, internationally recognized standard for determining the Life Cycle Assessment (LCA) of a product. The LCA examines the product’s entire lifecycle—from manufacturing and shipping to treatment and eventual disposal. By publishing this data, we are taking an important step towards making the environmental impact of our products fully transparent.

What Is Global Warming Potential (GWP)?

Global warming potential refers to how much heat a greenhouse gas traps in the atmosphere over a specified time period, usually 100 years, relative to carbon dioxide (CO₂). Greenhouse gases contribute to global warming by absorbing energy and slowing the rate at which this energy escapes into space. We measure this potential by calculating CO₂ equivalents (CO₂e), which allow us to compare the impact of different greenhouse gases on the environment. For example, methane has 28 times the global warming potential of CO₂, so its impact is measured as CO₂e.

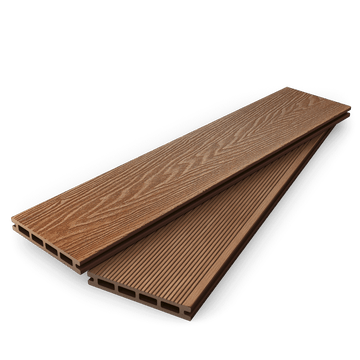

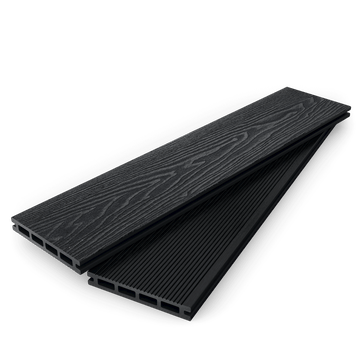

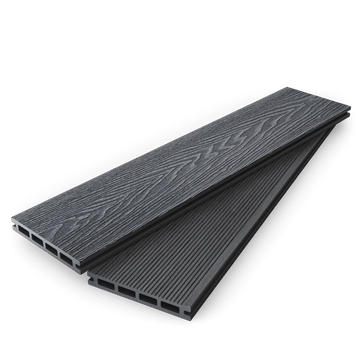

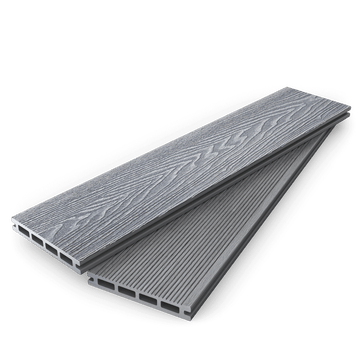

The Environmental Impact of Hyperion Composites

In the EPD for Hyperion Composite Products, we examine the CO₂e emissions generated at every stage of the product's lifecycle. This holistic approach provides a comprehensive understanding of the environmental impact, which goes beyond just the greenhouse gas emissions. We also looked at factors such as ozone depletion, water consumption, and harmful substance creation during production.

The results show that, when considering the entire lifecycle—from raw material processing to disposal—the Net CO₂e comes out to +1.53 kg per kg of composite. This means that for each kilogram of Hyperion composite, the overall environmental impact, taking into account all stages of the lifecycle, is positive but relatively low compared to other materials in the market.

Key Findings from the Life Cycle Assessment

-

Raw Material Processing: The process of converting waste wood and recycled plastic into composite material absorbs more CO₂ than it releases. This is because the waste wood used in production absorbs CO₂ during its growth phase, while recycled plastic contributes very little environmental impact.

-

Manufacturing Stage: The carbon footprint of the manufacturing stage is significantly reduced due to our transition to wind-powered energy. This has cut down 0.7 kg of CO₂ per kg of composite material produced. Without renewable energy, the carbon output would have been much higher, as highlighted by the striped section of the graph.

-

Disposal Stage: The disposal phase is the largest contributor to CO₂ emissions, primarily due to the product biodegrading and releasing its absorbed carbon back into the atmosphere. This phase has a substantial impact on the final environmental footprint of the composite products.

What Can EnviroBuild Do to Further Improve Sustainability?

The publication of the Environmental Product Declaration is just the beginning. We are committed to continuous improvement and actively seeking ways to reduce the environmental impact at every stage of the product lifecycle. While shifting our manufacturing process to wind energy has made a significant difference, there are other areas, like the disposal stage, where further improvements can be made.

Our focus is not just on offsetting emissions, but on reducing the environmental impact of the product directly. Offsetting doesn't eliminate the resource use or emissions during production—it simply compensates for them by reducing emissions elsewhere. We believe in actively lowering our product’s environmental impact from the very beginning, which is why we prioritize energy efficiency, sustainable sourcing, and the reduction of waste at every possible point in the lifecycle.

We are also constantly measuring and analyzing the environmental impact of all our products through LCAs and publishing more EPDs to ensure we remain transparent and focused on improvement. The move to wind energy in the production of Hyperion composite products was a crucial step, but we are far from done. We will continue to explore new and innovative ways to make our products more sustainable, while also keeping our commitment to transparency intact.

EnviroBuild's commitment to sustainability and transparency through the publication of its first Environmental Product Declaration is just the start of our journey. We are excited to continue improving and leading the way for the construction industry, showing that it is possible to build with the planet in mind.